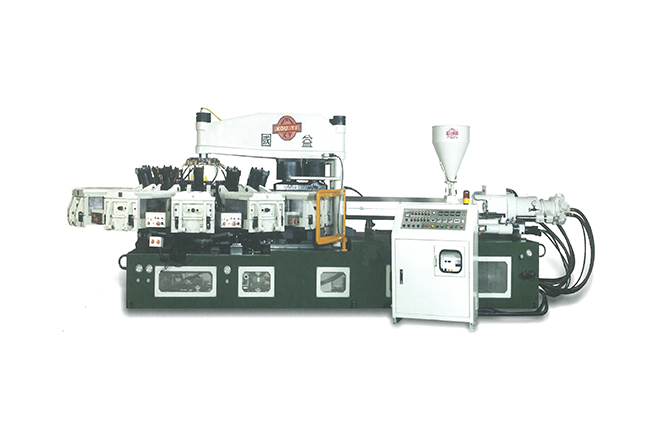

The single color/two color rain boots injection molding machine is special equipment used to produce rain boots made by PVC, TPR, TPE, and NBR material. We have experience over 35 years in the field of producing rain boots machinery and are constantly improving with the times. These machines are designed for efficiency and quality, operation easily, high clamping force to produce single/two-color rain boots.

Various types of plastic rain boots can be produced here, including rain boots, safety rain boots, snow boots and even sandals, etc. These machines come in different configurations. The standard model can produce the height up to 16 inches. The mold can open and close automatically with the air pressure automatic demoulding system. It will protect the last and extend the life of the mold.

Features of single color / double color rain boot injection machines include:

- Computer control: This machine adopts fully automatic computer control, PLC, and HCI control, which is easy to operate. It can set process parameters for different molds separately and can automatically detect the machine system. Make maintenance time short and easier to maintain.

- Injection control: Injection is controlled by computer, and combined with the injection self-control auxiliary device. The injection volume control is more precise, easier to operate, and the production is stable.

- High-pressure injection: This machine uses computer direct pressure injection. Set in stages according to the requirements of the product to ensure product quality.

- High clamping force: The whole machine follows hydraulic system to run. There is strong clamping pressure, and reliable mold closing which helps to maintain product integrity during the injection process. The product has good uniformity and does not produce any flash.

- Special hydraulic system: This machine adopts special logic oil circuit design to make the machine run in high speed and efficiency. The shift device with hydraulic oil makes low noise and accurate positioning.

- Automatic mold opening: The machine can automatically open and close with the pneumatic demoulding system. The finished product can be more easily removed from the mold without damaging the shoe last.

- Simultaneous production: With a unique stacked injection device that can inject different colors / materials of the soles and uppers at the same time. Reducing production time and improving efficiency.

- Versatility: This machine can produce various types of footwear at the same time, including general rain boots, safety rain boots, snow boots, etc.

- Safety protection: CE safety certified, multiple safety protection systems ensure personnel and safety.

- Other robots: Equipped with an automatic gripping mechanical arm to grip the residual material from the material channel. An additional automatic arm can also be added to pick up the finished product to reduce labor intensity.